We have some very interesting test infrastructure at our disposal on our campuses where our researchers can perform tests for your verifications

Infrastructure

E-cube | Zero Energy Test House

The E-cube is a zero energy test house for researchers developing energy efficient building components and systems. It is a full scale test facility, operated by the Research Group Building Physics of Ghent University, to investigate innovations designed for the zero energy buildings of the future in realistic climatic conditions.

Recent research contributes to the development of energy efficient ventilation systems, and investigates the influence of environmental parameters (wind speed, direction, solar irradiance, temperature, relative humidity) on the indoor air quality with particular focus on volatiles released by building materials

In 2011 the E-cube participated in the worldwide solar Decathlon competition in the US, a contest among universities to design and build a solar energy driven house. The E-cube was 16th in the global competition and won 1st prize for the most affordable dwelling.

Research topics

-

In-situ performance of energy systems

-

Energy neutral construction concepts

-

Quality of the indoor environment

-

Building physical performance of building components

-

Validation of simulation models for energy use and indoor air quality in buildings

-

Downpour load on facades

Principles of design

-

Passive house principles

-

Affordable and modular DIY package

-

Phased: upgrades with extensions

-

Plug and play for all techniques

-

Structural flexibility: pallet racks as load-bearing elements

Pictures: Beeldbank UGent

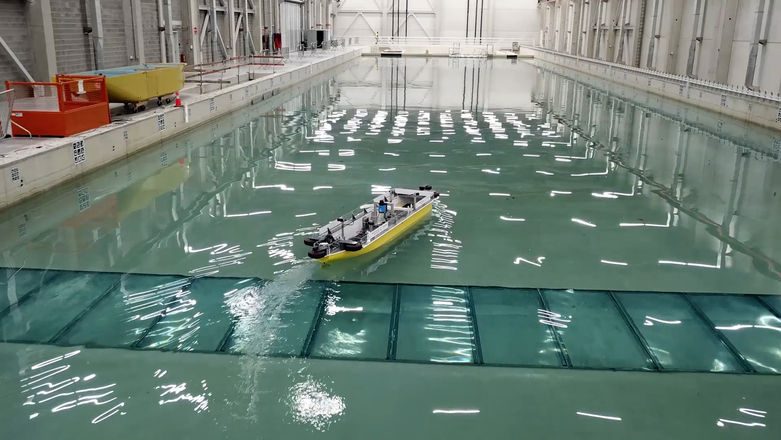

Coastal & Ocean Basin

Location:

Contact:

Flanders Maritime Laboratory, Wetenschapspark 8, 8400 Oostende

The Coastal & Ocean Basin (COB) wave tank facility in Ostend (Belgium) has been designed to study the effect of waves and currents on coastal and offshore engineering scale models, as well as the hydrodynamic behaviour of floating and marine renewable energy devices. With wave tank dimensions of 30 m x 30 m, a variable water depth up to 1.4 m and a central pit with up to 4.5 m water depth, the infrastructure offers excellent test conditions for coastal to near offshore applications.

The state-of-the-art generation and measurement systems boast several unique features, such as the ability to generate waves and current at any relative angle. Extreme directional wave conditions with a wave height up until 0.55 m can be generated, in combination with maximum current velocities of 0.4 m/s. The Qualisys motion capture system, a unique twin system of above and underwater cameras, enables users to accurately capture 6-Degree-of-Freedom motions of floating or semi-submersed objects. The wide range of testing possibilities includes – but is not limited to – coastal defence solutions, renewable energy technologies such as offshore (floating) wind turbines, wave energy converters or floating photovoltaic systems, as well as capturing seagoing ship motions, testing of marine observation equipment or mooring applications.

The Coastal & Ocean Basin is situated within Flanders Maritime Laboratory, which also houses a towing tank for manoeuvres in shallow water. The COB is managed by a consortium composed of Ghent University, KU Leuven and Flanders Hydraulics Research. Fully operational since first half of 2023, the COB welcomes users from academia, industry and governmental institutions.

Labo Lemcko

We use our research equipment to detect your voltage dips, harmonics, imbalance, flicker, EMC problems. You want to know which measurements and analyzes we do in our lab? Discover which troubleshooting we perform for you:

-

Test field PV systems | Test different technologies side by side in various setups

-

Test field for decentralized production and storage | Realistic distribution grid with different grid configurations, Power injection from PV park, Freely adjustable grid quality up to 180 kVA

-

DC Net | DC bus energy storage

-

Generator test bench (grid-emulator) | Wind turbine emulator up to 150 kW, GenSet & CHP emulator at different synchronous speeds, Emulation of electric vehicles and impact on the grid

-

EMC lab | Semi-anechoic cage in EMC lab

-

Power Quality lab | Freely adjustable grid quality up to 180kVA

Pictures: Labo Lemcko

HomeLab

HomeLab is a unique residential test and co-innovation environment for smart home services of 600 m2 in Ghent, Belgium. HomeLab is both a lab and a real two-story house in which people can live temporarily to test and co-create IoT services. It supports innovation from brainstorming, over early proof-of-concept testing to pre-pilot testing in a real living environment for a variety of application domains (home automation, health & care, energy, social robotics, audio & video, AR/VR, etc.).

Technical corridors, hollow floors and ceilings allow to add and hide new devices and prototypes ensuring a natural interaction with the services under development and test. An extensive sensor infrastructure captures relevant context information (temperature, air quality, energy consumption, user presence, etc.) supporting in-depth analyses of the performed experiments. Via an open home automation system all functional elements (HVAC, blinds, curtains, switches, doors, windows, etc.) can be controlled and monitored. The captured sensor and actuator data are stored in a scalable and secure data platform providing access to real-time and historical data.

HomeLab aims at serving the needs of different stakeholders including SMEs as well as large businesses, researchers, non-profit organizations, etc. HomeLab is also ideally suited for organizing brainstorms, demonstrations, hackatons, trainings, and even small-scale events.

Example use cases for which HomeLab could be used:

-

Detection of typical residential user activities & lifestyle patterns for home automation and assisted living services

-

Validation of smart home energy management systems with real assets

-

User interaction with social robots

-

Subjective video quality testing

-

Evaluation of residential AR/VR services

-

Accurate speech recognition in (challenging) home environments

-

IoT interoperability testing

-

...

Pictures: IDLab

STFES Lab

The STFES lab, which stand for 'Sustainable Thermo-Fluid Energy Systems', is a state-of-the-art laboratory for both fundamental research and industrial services. It is broadly divided to accommodate engine test cells and research in thermodynamics and heat transfer.

Thermodynamics and heat transfer

-

Measurement of thermal conductivity of building materials using the guarded hot plate method

The guarded hot plate method is a steady-state measurement method that determines the thermal conductivity of a material by using the electrical power output of a hot plate with guided heat conduction.

-

Testing of heat pumps and other HVAC equipment

The testing of this equipment is carried out in a controlled environment which is simulated using a climate chamber. This test cell is designed according to the EN 14511 standards and is fitted with various components such as cooling batteries, fans, heaters, and humidifiers.

-

Performance evaluation of heat exchangers with gas and fluids

In the air-to-air heat exchanger test-rig we are able to measure the performance of heat exchangers. This can either be done with constant heat flux boundary conditions and one airflow to measure the heat transfer capabilities of one side. For example, a new fin design. Another possibility is to use two air streams to measure the performance of a heat exchanger.

-

Flow calorimeter for measuring fluid thermal properties

The calorimeter is used to measure the isobaric specific heat capacities of different fluids and consists of a stainless steel inner tube, a micro heater, a vacuum pump, a vacuum chamber around the inner tube, an aluminum radiation shield, and exterior insulation.

-

Organic Rankine Cycles (ORC’s) high-temperature heat pump testing for industry

The test facility is equipped to test ORC’s and high-temperature heat pumps with 300kW heating and 250kW cooling capacities. These test facilities are also used to test the performance medium-large scale phase change material (PCM) energy storage units. The lab is situated on the Kortrijk campus of Ghent university.

Engine test cells

-

Cooperative Fuel Research (CFR) Engine

The CFR engine is a spark ignited single-cylinder engine with a variable compression ratio. It is used to perform fundamental investigation on the behaviour of experimental and/or sustainable fuels. Because of the versatility of this research engine, alternative combustion methods like Low Temperature Combustion (LTC) or Homogeneous Charge Compression Ignition (HCCI) combustion techniques can be investigated as well.

-

Volvo T3 engine

The Volvo T3 engine is a state-of-the-art spark ignited turbocharged production engine, equipped with a fully programmable engine control unit and a high-speed combustion analysis system. It allows for performance- and emission measurements of experimental alternative and/or sustainable fuels in real-life engine conditions for light-to-medium duty applications.

-

Toyota D4D engine

The Toyota D4D engine is a late-generation, turbocharged common rail diesel engine. The stock engine control unit has been replaced with a fully programmable unit and a high-speed combustion analysis system. It allows for performance- and emission measurements of experimental alternative and/or sustainable diesel fuels in real-life engine conditions.

-

Volva Penta

The Penta engine is a medium-to-heavy duty marine diesel engine which can be operated in diesel, dual-fuel (diesel/methanol) or spark ignition mode. The versatility of this engine allows for fundamental research on different experimental and/or sustainable fuels that can be used together (dual-fuel) or separately (diesel or spark ignited). It features a fully programmable engine control unit and advanced data capturing system, allowing for advanced combustion analysis.

-

GUCCI (Ghent University Combustion Chamber I)

The GUCCI is a sophisticated Constant Volume Combustion Chamber with a high-speed optical data measurement system. It allows for analysis of injection spray behaviour in a combustion chamber at different combustion chamber pressure and temperature conditions, which is important for suitability testing of experimental and/or sustainable fuels in existing or newly designed fuel injection systems.

Pictures: STFES Lab

Test Centre for Façade Components

Since it was founded in 1948, the Test Centre for Façade Components has been dedicated to support R&D and certification of building products for 75 years. By combining experimental work, on site assessment, and numerical simulations using commercial software as well as in-house models, it has provided support to national and international partners to assess, improve and innovate façade technology. The initial focus of the lab was on windows systems, but over the last decade this has expanded towards cavity walls, ventilated façade systems, heritage masonry walls, wood-frame construction, CLT, double skin façades, and building envelope interfaces in general. Next to that, the lab has invested continuously in material characterization for hygrothermal performance assessment.

Research topics:

-

Airtightness

-

Watertightness

-

Thermal performance

-

Hygrothermal modelling

-

Pressure equalization

-

Moisture storage properties

-

Moisture transport properties

Furthermore, the Test Centre for Façade Components works in close collaboration with other labs at Ghent University to use test infrastructure, amongst which Woodlab, PProgress, UGCT, and DuraBUILDmaterials.

Pictures: Façade Components Lab

Shallow Water Towing Tank

Location:

Contact:

Flanders Maritime Laboratory, Wetenschapspark 8, 8400 Oostende

The Towing Tank for Manoeuvres in Shallow Water (co-operation Flanders Hydraulics and Ghent University) consist out of a tank of 174 m by 20 m, a water basin the same size to store the water and a fully automated carriage which runs tests 24/7. This towing carriage can test ship models (or other floating devices) up to 8m long. The carriage is automated since a large number of parametric variations are necessary to achieve enough data to build an accurate mathematical model of the ship behaviour, especially when covering manoeuvres in shallow or confined water.

The facility is also equipped in order to be able to perform free running model tests. In this configuration the ship model is not dragged through the water via the carriage, but sails with its own propulsion unit (propeller(s) and rudder(s)). The position of the ship model is then accurately measured via Lidar, inertial measurement and cameras (ArUco markers) and torque and forces measured on propeller(s) and rudder(s).

This new and unique facility, owned by Flanders Hydraulics, is run in cooperation with Ghent University.

Equipment

Equipment is renewed at regular times and in-house technical team is available to perform customization upon project requirement.

-

Force dynamometers ; Vertical motions at up to four positions per model

-

Propeller rotation, thrust and torque measurement; testing of L-drives, Z-drives, lateral thrusters,…

-

Rudder forces (longitudinal, transversal, moment) and angle measurement

-

Wave height measurement devices; Pressure cells (hull attachment)

Applications

-

Ship models range 3.5 m to 8.0 m.

-

Shorter models can perform versatile manoeuvres (e.g. turning circle, obstacle avoidance)

-

Longer models are used to focus on digital twins and resistance and propulsion

-

Captive test matrix (variation of water depth, draft, speed...) -> digital twin ship for shallow and confined conditions

-

Resistance and propulsion tests in shallow and confined conditions

-

Specialised programs in shallow and confined water for ship-ship interaction, bank effects,…

-

Tuning (captive, free running) and validation (free running) of track controls for autonomous shipping

Dimensions shallow water towing tank

-

Total length: 174.0 m

-

Width: 20.0 m

-

Maximum water depth: 1.0 m

-

Length of ship models: 3.5 to 8.0 m

Pictures: Flanders Maritime Laboratory

Confined Water Towing Tank

The Towing Tank for Manoeuvres in Confined Water (co-operation Flanders Hydraulics and Ghent University) had the first fully automated and unmanned towing carriage in the world (and today only a handful others exist) and has been running since 1992. It consist of a shallow water towing tank (88m by 7m), equipped with a planar motion carriage, a wave generator and an auxiliary carriage for ship-ship interaction tests. The facilities are fully computer controlled and operated, both in captive and in free running mode, so that experimental programs are running day and night, 7 days a week.

This facility, owned by Flanders Hydraulics, is run in cooperation with Ghent University.

Instrumentation

-

4 x 2 dynamometers for longitudinal and lateral forces

-

dynamometers for roll moment;

-

measurement of propeller rpm;

-

3 propeller thrust and torque dynamometers

-

measurement of vertical motion (due to squat or wave action) at 4 measuring posts;

-

measurement of rudder angle;

-

5 rudder force and moment dynamometers

-

wave height measurement devices

-

custom instrumentation such as Z-drives, lateral thrusters, etc. with steering capabilities and force measurements;

-

visuals system to assess water and wave actions.

Applications

Determination of manoeuvring simulation models by means of captive model tests, with special emphasis on harbour manoeuvres:

-

large range of ship speeds (ahead and astern)

-

large drift angles

-

rudder action

-

large range of propeller rates (ahead and astern)

-

very shallow water (typical under keel clearance: 7 to 20% of draft

Manoeuvring behaviour in restricted waters:

-

bank effects;

-

navigation in canals;

-

berthing;

-

ship-ship interaction tests;

-

captive seakeeping tests, for investigating vertical ship motions caused by waves in shallow water and/or manoeuvring in waves;

-

free running tests: zigzag trials, acceleration tests, crash stops etc.

Dimensions Confined Towing Tank

-

total length: 88.0 m

-

width: 7.0 m

-

Maximum water depth: 0.5 m

-

Length of ship models: 2.0 to 4.5 m

Pictures: Flanders Hydraulics

Full mission bridge simulators

Flanders Hydraulics has three in house developed and maintained simulators: SIM 360+; SIM 225 and Lara. The first two allow sailing simulations with various types of ships such as seagoing vessels, coasters and tugboats. Lara is a ship manoeuvring simulator dedicated for inland vessels only.

The simulators are mainly used for research but also for training (pilots and maritime academy). During research, the experienced navigators are provided a manoeuvring task and afterwards, a statistical analysis of these manoeuvres are carried out. This allows the condition to be evaluated and, for example, to estimate the feasibility. Different types of simulation research can be carried out:

-

design ports and waterways;

-

optimize nautical procedures;

-

determine the limits for safe traffic (risk analysis).

Characteristics

Ship’s bridge:

-

navigation equipment for steering various types of vessels (seagoing, coastal shipping and Voith-Shneider tugboats);

-

automatic radar plot device (ARPA radar);

-

quadrophonic sound system;

-

VHF radio;

-

Electronic Chart Display Information System (ECDIS);

-

possibility to connect Portable Pilot Unit.

Exterior visuals:

-

computer-generated perspective image of the surroundings projected on a cylindrical screen;

-

under projection, a surplus value for quay and lock manoeuvres (you can look down from the bridge);

-

fog, mist, twilight and night vision.

Mathematical manoeuvring model:

-

calculation of hydrodynamic forces, shallow water effects, restricted water effects;

-

propulsion;

-

aerodynamic forces;

-

forces induced by tugboats;

-

forces of mooring lines and anchors;

-

contact forces and interaction with encountering and overtaking target vessels.

Instructor’s room:

-

operator console to select, develop, start and stop voyages;

-

control of target vessels;

-

set atmospheric conditions and the time of day;

-

opening and closing of bridges and lock gates;

-

operate traffic lights;

-

operating console for 4 tugboats (classic, Voith-Schneider, Z-Peller).

Pictures: Flanders Hydraulics

Test Rig for energy-efficient electric drivetrains & components

Location:

Contact:

UGent campus Kortrijk, building A, Sint-Martens-Latemlaan 28, 8500 Kortrijk

The large-scale test bench in Kortrijk is designed to test various combinations of drivetrain components and systems such as motors, generators, transmissions and power electronics up to 150kW, 6000rpm and 45kNm. We can perform traditional load profile tests to generate accurate efficiency maps, test machine level control, condition monitoring/control and dynamics of drives (DOL or with freq. regulator). Via Hardware-in-the-Loop (HiL) realistic load profiles can be emulated to mimic the behaviour of wind and wave energy turbines, electric vehicles or industrial machines. The test bench is furthermore equipped with a calorimeter for advanced thermal characterization of drivetrain systems and components. It allows to build-up and/or validate detailed power loss models with very high accuracy and even determine the overall efficiency for repetitive dynamic motion profiles. A high-speed thermal camera is also available for rental and can be used to identify fast rotating hotspots, analyse thermal component interaction, cross-check calculated system temperature distribution and validate IR sensors. The calorimeter and thermal camera of the setup is funded by Flanders Make project Ithaca.

If needed, tailored test campaigns and setups can be designed based on your needs.

Key specifications

-

Max. power rating: 150kW continuous; max. rotational speed: 6000rpm; max. torque: 45kNm

-

Programmable power sources (AC: 440V/180kW; DC: 800V.180kW).

-

Max. dimensions of test object for thermal characterization: 1.3m x 1.0m x 1.8m

-

Accuracy of power loss models within <1% error margin

-

High-speed thermal camera with framerate of 233Hz and range -40°C to 1200°C

Pictures: Test rig for energy-efficient electric drivetrains & components